Photo from wikipedia

The enzymatic esterification of oleic acid and 1-butanol to butyl oleate was performed in an aqueous–organic system in capillary microreactors with various inner diameters operated under slug flow. The free… Click to show full abstract

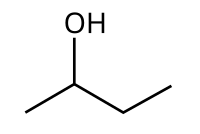

The enzymatic esterification of oleic acid and 1-butanol to butyl oleate was performed in an aqueous–organic system in capillary microreactors with various inner diameters operated under slug flow. The free Rhizomucor miehei lipase in the aqueous phase was used as a catalyst and n-heptane as the organic solvent. A close to 100% yield of butyl oleate could be achieved in the microreactor made of polytetrafluoroethylene within 30 min residence time at 30 °C. The reaction rate is well described by the existing kinetic model based on a Ping Pong Bi Bi mechanism with competitive inhibition of 1-butanol. This model was extended to describe the effect of the interfacial area and aqueous-to-organic flow ratio in microreactors. By performing the reaction at low aqueous-to-organic flow ratios in hydrophilic microreactors (e.g., made of stainless steel), the enzyme turnover number could be enhanced significantly, making it promising for process intensification.

Journal Title: Industrial & Engineering Chemistry Research

Year Published: 2019

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!