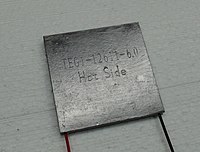

Photo from wikipedia

To achieve high-performance thermoelectric (TE) devices, constructing good interfacial connection between TE materials and electrodes is as important as having high figure-of-merit TE materials. Although CoSb3-based TE devices have received… Click to show full abstract

To achieve high-performance thermoelectric (TE) devices, constructing good interfacial connection between TE materials and electrodes is as important as having high figure-of-merit TE materials. Although CoSb3-based TE devices have received great attention for power generation recently, the limited long-term service stability is the main obstruct for their applications. In this work, we have prepared two kinds of Ti-based alloys (Ti83.7Al10.7Si5.6 and Ti74Ni26) as the diffusion-barrier layer of CoSb3-based TE joints by the spark plasma sintering method, and have systematically investigated their interfacial behaviors during the aging process. The performance of the contact resistivity and mechanical strength for the Ti74Ni26/Yb0.4Co3.8Fe0.2Sb12 TE joints are good before aging treatment, but gradually deteriorate during the aging process, which should be ascribed to the phase-transition induced negative thermal expansion in Ti-Ni alloys. On the other hand, the Ti83.7Al10.7Si5.6/Yb0.4Co3.8Fe0.2Sb12 TE joints show both low contact resistivity (<10 μΩcm2) and high mechanical strength (> 20 MPa) before and after 16-day aging at 500 oC, which is originated from the matching of coefficient of thermal expansion (CTE) and the formation of network structures in the Ti-Al-Si alloys. We have also prepared an 8-couple TE module of p-Ge0.9Sb0.1TeB0.01/n-Yb0.4Co3.8Fe0.2Sb12 and have measured its corresponding device performance. Our work has demonstrated that the matched CTE and network structures in the Ti-Al-Si alloy are the keys to obtain high-performance CoSb3-based TE joints for long-term service.

Journal Title: ACS applied materials & interfaces

Year Published: 2020

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!