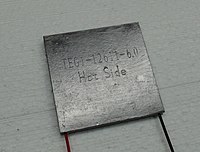

Photo from wikipedia

Flexible thermoelectric materials and devices show great potential to solve the energy crisis but still face great challenges of high cost, complex fabrication, and tedious postprocessing. Searching for abnormal thermoelectric… Click to show full abstract

Flexible thermoelectric materials and devices show great potential to solve the energy crisis but still face great challenges of high cost, complex fabrication, and tedious postprocessing. Searching for abnormal thermoelectric materials with rapid and scale-up production can significantly accelerate their applications. Here, we develop superlarge 25 × 20 cm2 commercial graphite-produced composite films in batches, achieved by a standard 10 min industrial process. The high cost effectiveness (S2σ/cost) of 7250 μW g m-1 K-2 $-1 is absolutely ahead of that of the existing thermoelectric materials. The optimized composite film shows a high power factor of 94 μW m-1 K-2 at 150 °C, representing the optimal value of normal carbon materials so far. Furthermore, we design two types of flexible thermoelectric devices fabricated based on such a novel composite, which achieve an output open-circuit voltage of 3.70 mV using the human wrist as the heat source and 1.33 mV soaking in river water as the cold source. Our study provides distinguished inspiration to enrich flexible and cost-effective thermoelectric materials with industrial production.

Journal Title: ACS applied materials & interfaces

Year Published: 2022

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!