Photo from wikipedia

Controlling the pressure at which liquids intrude (wet) and extrude (dry) a nanopore is of paramount importance for a broad range of applications, such as energy conversion, catalysis, chromatography, separation,… Click to show full abstract

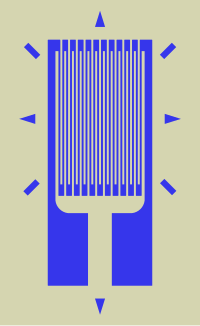

Controlling the pressure at which liquids intrude (wet) and extrude (dry) a nanopore is of paramount importance for a broad range of applications, such as energy conversion, catalysis, chromatography, separation, ionic channels, and many more. To tune these characteristics, one typically acts on the chemical nature of the system or pore size. In this work, we propose an alternative route for controlling both intrusion and extrusion pressures via proper arrangement of the grains of the nanoporous material. To prove the concept, dynamic intrusion–extrusion cycles for powdered and monolithic ZIF-8 metal–organic framework were conducted by means of water porosimetry and in operando neutron scattering. We report a drastic increase in intrusion–extrusion dynamic hysteresis when going from a fine powder to a dense monolith configuration, transforming an intermediate performance of the ZIF-8 + water system (poor molecular spring) into a desirable shock-absorber with more than 1 order of magnitude enhancement of dissipated energy per cycle. The obtained results are supported by MD simulations and pave the way for an alternative methodology of tuning intrusion–extrusion pressure using a macroscopic arrangement of nanoporous material.

Journal Title: ACS Applied Materials & Interfaces

Year Published: 2022

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!