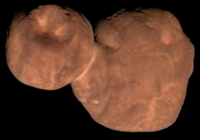

Photo from wikipedia

The adoption of neat-fullerene (C60 and C70) in polymer solar cells offers opportunities to develop cost-effective and thermally stable devices. Here, through rational side-chain engineering of low optical-gap polymer poly(benzodithiophene-furan-diketopyrrolopyrrole)s… Click to show full abstract

The adoption of neat-fullerene (C60 and C70) in polymer solar cells offers opportunities to develop cost-effective and thermally stable devices. Here, through rational side-chain engineering of low optical-gap polymer poly(benzodithiophene-furan-diketopyrrolopyrrole)s (PBDs), we demonstrated for the first time a polymer/C70 blend exhibited higher efficiency (best 6.1%) compare to their polymer/[70]PCBM (best 5.7%) counterparts, and the best efficiency is at the front of efficient polymer/neat-fullerene solar cells. More importantly, we first demonstrated the morphology optimization methodology for solution-processed polymer/neat-fullerene blends in order to reduce the strong crystallization and aggregation of neat-fullerene molecules. In comparison with previous work, these results can provide not only material design strategy but also fundamental difference between polymer/neat-fullerene and polymer/PCBM blend morphology, which allow us better understanding of how to choose proper materials and optimize blend morphology in polymer/neat-fullerene based device to deliver higher photovoltaic performance.

Journal Title: ACS applied materials & interfaces

Year Published: 2018

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!