Photo from wikipedia

Aliphatic polycarbonates represent an important class of materials with diverse applications ranging from battery electrolytes, polyurethane intermediates, and materials for biomedical applications. These materials can be produced via the ring-opening… Click to show full abstract

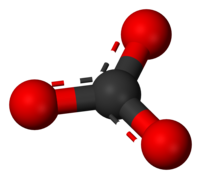

Aliphatic polycarbonates represent an important class of materials with diverse applications ranging from battery electrolytes, polyurethane intermediates, and materials for biomedical applications. These materials can be produced via the ring-opening polymerization (ROP) of six- to eight-membered cyclic carbonates derived from precursor 1,3- and 1,5-diols. These diols can contain a range of functional groups depending on the desired thermal, mechanical, and solution properties. Generally, the ring closure to form the cyclic carbonate requires the use of undesirable and hazardous reagents. Advances in synthetic methodologies and catalysis have enabled the use of carbon dioxide (CO2) to perform these transformations with a high conversion of diol to cyclic carbonate, yet modest isolated yields due to oligomerization side reactions. In this Letter, we evaluate a series of bases in the presence of p-toluenesulfonyl chloride and the appropriate diol to better understand their effect on the yield and presence of oligomer byproducts during cyclic carbonate formation from CO2. From this study, N,N-tetramethylethylenediamine (TMEDA) was identified as an optimal base, facilitating the preparation of a diverse array of both six- and eight-membered carbonates from CO2 within 10 to 15 min. The robust conditions for both, the preparation of the diol precursor, and the TMEDA-mediated carbonate synthesis enabled readily telescoping the two-step reaction sequence, greatly simplifying the process of monomer preparation.

Journal Title: ACS macro letters

Year Published: 2022

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!