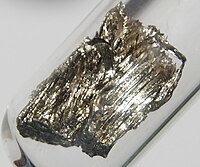

Photo from wikipedia

In order to investigate the effects of Sm2O3 as a promoter on catalytic performance, ordered mesoporous NiO–Sm2O3–Al2O3 catalysts were synthesized by a facile one-pot evaporation-induced self-assembly (EISA) method and used… Click to show full abstract

In order to investigate the effects of Sm2O3 as a promoter on catalytic performance, ordered mesoporous NiO–Sm2O3–Al2O3 catalysts were synthesized by a facile one-pot evaporation-induced self-assembly (EISA) method and used in the CO methanation reaction to produce synthetic natural gas. Besides, the ordered mesoporous catalysts prepared by the conventional impregnation method together with unordered mesoporous catalysts were selected as references. These catalysts were characterized by scanning electron microscopy, transmission electron microscopy, N2 adsorption, X-ray diffraction, H2 temperature-programmed reduction, X-ray spectroscopy, and thermogravimetric analysis. The results revealed that the ordered mesoporous catalysts synthesized by the one-pot EISA method showed enhanced catalytic performance for CO methanation compared with those prepared by the impregnation method. The addition of the Sm species can further improve the catalytic activity, and the ordered mesoporous 20N6SOMA catalyst with 20 wt% NiO and 6 wt% Sm2O3 species was the best. Our characterization results showed that Sm2O3 could improve the reducibility of Ni particles and decrease the Ni particle sizes; the majority of Sm species were in the form of Sm3+ (Sm2O3) together with a small amount of Sm2+ (SmO) over the reduced catalysts. The Sm3+/Sm2+ redox could increase the electron cloud density of Ni, which resulted in intensified catalytic activity over the ordered mesoporous NiO–Sm2O3–Al2O3 catalyst. Moreover, the optimal ordered mesoporous 20N6SOMA catalyst showed high stability in a 101 h lifetime test at 550 °C and 0.1 MPa due to its excellent confinement effect.

Journal Title: New Journal of Chemistry

Year Published: 2018

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!