Photo from wikipedia

The complete conversion of hemicellulose, cellulose and lignin in lignocellulosic biomass into value-added chemicals is of great significance in biorefinery processes. Herein, a cascade-step strategy was developed for the conversion… Click to show full abstract

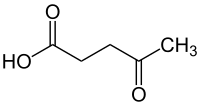

The complete conversion of hemicellulose, cellulose and lignin in lignocellulosic biomass into value-added chemicals is of great significance in biorefinery processes. Herein, a cascade-step strategy was developed for the conversion of hemicellulose and lignin into mixed organic acids, and cellulose into ethylene glycol. Typical biomass of Miscanthus was first treated with formic acid in the presence of H2O2, giving a formic acid solution and cellulosic biomass. Lignin in Miscanthus was oxidized to low polymerized organic acids through linkage cleavages and aromatic ring ruptures during the treatment process, forming a homogeneous formic acid solution with a weight yield of 95%. Hemicellulose was transformed into maleic acid at 56.2% selectivity via a hydrolysis–dehydration–oxidation process. Both hemicellulose and lignin were degraded into organic acids with an overall weight yield of 92.4%. The cellulose in the solid residue had a hydrophilic surface and is highly accessible to catalysts in the aqueous solution, and it was totally converted into ethylene glycol with a yield of up to 65.7% over a binary catalyst of H2WO4–Ru/C. Relying on such a cascade reaction strategy, the three major components of Miscanthus were transformed into mixed organic acids and ethylene glycol, which provides a potential strategy for complete valorisation of biomass into value-added chemicals.

Journal Title: Green Chemistry

Year Published: 2021

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!