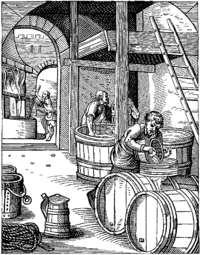

Photo from wikipedia

ABSTRACT The brewing process differs slightly in craft breweries as compared to industrial breweries, as there are fewer control points. This affects the microbiota of the final product. Beer contains… Click to show full abstract

ABSTRACT The brewing process differs slightly in craft breweries as compared to industrial breweries, as there are fewer control points. This affects the microbiota of the final product. Beer contains several antimicrobial properties that protect it from pathogens, such as low pH, low oxygen and high carbon dioxide content, and the addition of hops. However, these hurdles have limited power controlling spoilage organisms. Contamination by these organisms can originate in the raw materials, persist in the environment, and be introduced by using flavoring ingredients later in the process. Spoilage is a prominent issue in brewing, and can cause quality degradation resulting in consumer rejection and product waste. For example, lactic acid bacteria are predominately associated with producing a ropy texture and haze, along with producing diacetyl which gives the beer butter flavor notes. Other microorganisms may not affect flavor or aroma, but can retard fermentation by consuming nutrients needed by fermentation yeast. Quality control in craft breweries today relies on culturing methods to detect specific spoilage organisms. Using media can be beneficial for detecting the most common beer spoilers, such as Lactobacillus and Pediococci. However, these methods are time consuming with long incubation periods. Molecular methods such as community profiling or high throughput sequencing are better used for identifying entire populations of beer. These methods allow for detection, differentiation, and identification of taxa.

Journal Title: Critical Reviews in Food Science and Nutrition

Year Published: 2019

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!