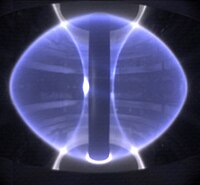

Photo from wikipedia

Abstract The Active Gas Handling System (AGHS) collects Tokamak exhaust gases from the JET machine and recovers, purifies and recycles the deuterium and tritium for fuelling the plasma. With the… Click to show full abstract

Abstract The Active Gas Handling System (AGHS) collects Tokamak exhaust gases from the JET machine and recovers, purifies and recycles the deuterium and tritium for fuelling the plasma. With the increasing fusion power and all-metal first wall and diverter, the forthcoming DTE2 experiment will see a change in the Tokamak exhaust composition compared to the DTE1 first series of experiments. A range of gases additional to those for fuelling the plasma will be added for critical applications such as plasma detachment and disruption mitigation. One of these candidate gases is neon, which is anticipated to have a negative influence on storing the recovered hydrogen at an early stage of AGHS reprocessing. This paper will outline the trials and plant modifications which are in hand to provide a solution and enable downstream processes to operate as during DTE1. This will comprise a scrubbing circuit to mitigate the blanketing action of the neon in sorbing the hydrogen isotopes onto the existing depleted-uranium metal-hydride storage beds. A second approach is also under study that has the potential to bring the tritium process circuit into closer alignment to that intended by ITER, thus providing process data for supporting the ITER fuel cycle design and increasing further the value of the JET experiments to the ITER project. JET’s torus gases recovered onto AGHS’s ITER Prototype Cryosorption Pump (PCP) will, on regeneration, be representative of the gas compositions received into ITER’s Tokamak Exhaust Processing (TEP) system front end. The following adaptions of AGHS are being considered to make processing more representative of ITER: 1. Helium, neon and hydrogen isotopes from 80 K regenerations of the PCP could be routed directly to a Pd-Ag permeator that will replicate the first stage of TEP hydrogen processing. 2. Other gases liberated from regenerating the PCP at 130 K (so-called “warm” regenerations) could be cycled around a nickel bed and permeator train that will approximate to the operation of a palladium membrane reactor which is a second processing route within the TEP system.

Journal Title: Fusion Science and Technology

Year Published: 2017

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!