Photo from wikipedia

Abstract Condition-based maintenance (CBM) should be derived carefully to reduce maintenance costs along with useless maintenance shifts and to predict ideal time to do the maintenance. In this paper, a… Click to show full abstract

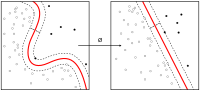

Abstract Condition-based maintenance (CBM) should be derived carefully to reduce maintenance costs along with useless maintenance shifts and to predict ideal time to do the maintenance. In this paper, a new method is proposed by the combination of data mining techniques and time series models to schedule maintenance activities. Considering a real database which contains failures and values of factors degrading the pump in the time of failure, a clustering algorithm is used to categorize failures based on the similarity in types of maintenance activities. Then, rules are extracted for characterizing the clusters and presenting a range for each factor by applying a proper association rule algorithm. Subsequently, time series models are applied to predict the time period that a factor may meet its rule’s range. Thus, a novel method is presented for a relative comparison between rules and predicted factor’s values and a prognostic scheduling is designed with respect to the effects of previous maintenance activities. The results of numerical experiments reveal that the proposed method can effectively determine when and which maintenance activities should be performed.

Journal Title: International Journal of Management Science and Engineering Management

Year Published: 2018

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!