Photo from wikipedia

2D rotary stages are applied in many manufacture equipment. Besides inherent geometric errors in each axis, the position and orientation errors between the two axes are also important position independent… Click to show full abstract

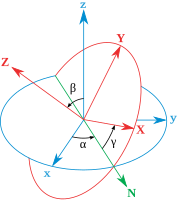

2D rotary stages are applied in many manufacture equipment. Besides inherent geometric errors in each axis, the position and orientation errors between the two axes are also important position independent geometric errors. Considering the existing methods for testing position and orientation are complex, a simple method is proposed. A laser diode is assembled on the end of the 2D rotary stage's transit axis, and a position sensitive device is used to test trajectories of laser spots when the transit axis rotates. Then, the standing axis rotates 180 degrees and the laser diode is assembled on the transit axis's another end. The same experiment is repeated, and the position and orientation errors of the two axes are separated by comparing the center positions of the two trajectories. The test errors of the position and the orientation error were less than 4μm and 1 arcsec according to calibration.

Journal Title: Measurement Science and Technology

Year Published: 2020

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!