Photo from wikipedia

Due to the harsh working environment, rotary machinery is susceptible to various faults, thus fault diagnosis to ensure safe operation is extremely important. Deep learning technology-based fault diagnosis is an… Click to show full abstract

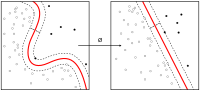

Due to the harsh working environment, rotary machinery is susceptible to various faults, thus fault diagnosis to ensure safe operation is extremely important. Deep learning technology-based fault diagnosis is an effective method but may face the following limitations. With the complexity of labeling fault signals and limitation of labeling experience, noisy labels are likely to be introduced, which affects the diagnosis result. So a framework called GRUS-CL is proposed, in which a baseline network combining a gated recurrent unit and softmax (GRUS) is trained by minimizing the correction loss (CL). First, two-dimensional transformation is proposed to form two-dimensional samples with less calculation time. Second, GRUS is designed to extract features and diagnose automatically. Third, an adaptive balance factor is introduced to form CL. The proposed GRUS-CL is evaluated with a bearing dataset and achieves the advantages of excellent diagnosis effect, simple structure, high noisy label tolerance, and discriminative feature extraction.

Journal Title: Measurement Science and Technology

Year Published: 2021

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!