Photo from wikipedia

Machine bottlenecks, resulting from shifting and unbalanced machine loads caused by resource capacity limitations, impair product-mix flexibility production systems. Thus, the knowledge base (KB) of a dynamic scheduling control system… Click to show full abstract

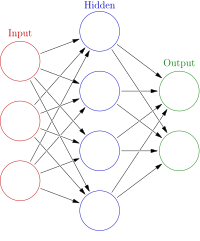

Machine bottlenecks, resulting from shifting and unbalanced machine loads caused by resource capacity limitations, impair product-mix flexibility production systems. Thus, the knowledge base (KB) of a dynamic scheduling control system should be dynamic and include a knowledge revision mechanism for monitoring crucial changes that occur in the production system. In this paper, reinforcement learning (RL)-based dynamic scheduling and a selection mechanism for multiple dynamic scheduling rules (MDSRs) are proposed to support the operating characteristics of a flexible manufacturing system (FMS) and semiconductor wafer fabrication (FAB). The proposed RL-based dynamic scheduling MDSR selection mechanism consisted of initial MDSR KB generation and revision phases. According to various performance criteria, the presented approach yields a system performance that is superior to those of the fixed-decision scheduling approach, the machine learning classification approach, and the classical MDSR selection mechanism.

Journal Title: IEEE Access

Year Published: 2020

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!