Photo from wikipedia

Recent advances in additive direct-write circuit technology have enabled the fabrication of inductive winding geometries previously considered impossible by conventional methods. In this letter, a winding fabricated around a rectangular… Click to show full abstract

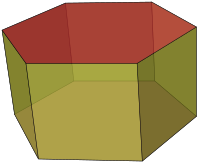

Recent advances in additive direct-write circuit technology have enabled the fabrication of inductive winding geometries previously considered impossible by conventional methods. In this letter, a winding fabricated around a rectangular cross-section toroidal core is considered. As an extension of research embedding toroidal cores within printed circuit board, this letter considers the minimization of the winding length when the vertical path, along the toroidal z-direction, is not restricted to be perfectly vertical, which is only possible with direct-write techniques. It will be shown that the exact analysis results in a transcendental equation for the optimized vertical midpoints of the winding turns. However, a few reasonable approximations allow an analytical expression for this optimized midpoint to be found. Comparisons of this approximate analytical solution to the exact solution found by numerical methods will be presented for typical toroid dimensions. The accuracy of this approximate solution with changing turn density will also be presented. For typical toroid dimensions, it was found that the choice of midpoint can change the total winding length by as much as 10%. The analytical approximate solution for the midpoint was found to deviate by 2.75% of angular gap from the exact solution, which resulted in an error in the minimum winding length of only 0.07%, a result which will be discussed in this letter.

Journal Title: IEEE Magnetics Letters

Year Published: 2020

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!