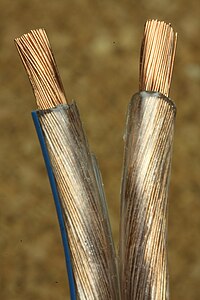

Photo from wikipedia

We have developed a thermo-compression soldering appliance for joining rare-earth barium copper oxide (REBCO) tapes with excellent control of process temperature and pressure. With this tool, we have systematically investigated… Click to show full abstract

We have developed a thermo-compression soldering appliance for joining rare-earth barium copper oxide (REBCO) tapes with excellent control of process temperature and pressure. With this tool, we have systematically investigated the effects of soldering parameters and solder materials on the electrical and mechanical performances of soldered joints between REBCO superconducting tapes with laminated copper stabilizers. Low resistivity of about 30 nΩ·cm2 at 77 K in self-field and high adhesion strength of about 5 N have been reproducibly achieved for lap joints with optimized process using InSn48 solder. The critical axial tensile stress of the joints was above 300 N, whereas the critical diameter for double bending of the joints was smaller than 20 mm. Lowering the temperature from 77 to 20 K reduced the joint resistance by 22%. However, applied magnetic fields up to 5 T showed little effect on the joint resistance. Increasing the overlapping joint length by N times dropped the joint resistance by a factor of about N−1. A 3-m-long lap joint of 5-mm-wide REBCO tapes showed a resistance as low as 0.3 nΩ at 77 K and self-field, which is the lowest resistance for soldered joint so far as we know.

Journal Title: IEEE Transactions on Applied Superconductivity

Year Published: 2019

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!