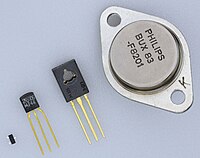

Photo from wikipedia

Recently, a wide class of market segments (e.g., health, material science, security, and communications) is tackled by circuits fabricated in BiCMOS technology, integrating silicon–germanium (SiGe) heterojunction bipolar transistors (HBTs) and… Click to show full abstract

Recently, a wide class of market segments (e.g., health, material science, security, and communications) is tackled by circuits fabricated in BiCMOS technology, integrating silicon–germanium (SiGe) heterojunction bipolar transistors (HBTs) and passives. Currently, the reliability of SiGe HBT devices is a major concern, and much attention is given to self-heating (SH), that limits device performance and regulates their degradation during stress. Moreover, its relevance is supposed to increase with device scaling. In this paper, we explore the reliability issues of SiGe HBTs by combining dedicated experiments and TCAD simulations. We develop and calibrate a TCAD model that is then used to investigate SH effects in both operating and stress conditions. Results show the important role played by the back-end-of-line (BEOL) and by the substrate thermal resistance in dissipating the heat generated by impact ionization. The location at which defects are generated during stress and the microscopic properties of the defects are determined experimentally by means of dedicated noise measurements. Including defects in the TCAD model allows reproducing the degradation observed in stress experiments. Simulations of the SH effects on a stressed device in measurement conditions revealed the presence of a hole hot spot that suggests a possible physical mechanism involved in the degradation slowdown at long stress times reported in the literature.

Journal Title: IEEE Transactions on Device and Materials Reliability

Year Published: 2019

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!