Photo from wikipedia

Heatsink design is critical for power density and reliability enhancement of power semiconductor modules. In this letter, an automated design and optimization methodology for air-cooled heatsinks are proposed based on… Click to show full abstract

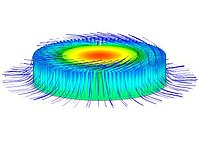

Heatsink design is critical for power density and reliability enhancement of power semiconductor modules. In this letter, an automated design and optimization methodology for air-cooled heatsinks are proposed based on genetic algorithm and finite element analysis. While the genetic algorithm generates a population of candidates with complex heatsink cross-section geometry in each iteration, finite element analysis is used to evaluate the fitness function of individual heatsink, i.e., junction temperature of semiconductor devices. With the rule of “survival of the fittest,” the proposed methodology eventually converges to an optimum heatsink design with the lowest device junction temperature. The optimized heatsink is fabricated through three-dimensional printing technology for thermal performance evaluation. Simulation and experimental evaluations have been conducted based on a 50-kW three-phase air-cooled inverter with the fabricated heatsinks. The comparative evaluation results show that the optimized heatsink is superior over a customized solution by 27% less in size and 6% lower in junction temperature.

Journal Title: IEEE Transactions on Power Electronics

Year Published: 2019

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!