Photo from wikipedia

Adhesively bonded structures are widely used to facilitate the manufacturing process and enhance the performance of critical components in the aerospace, automotive, and energy industries. The assessment of the bond… Click to show full abstract

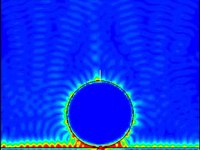

Adhesively bonded structures are widely used to facilitate the manufacturing process and enhance the performance of critical components in the aerospace, automotive, and energy industries. The assessment of the bond layer using the propagation of ultrasonic guided waves has been extensively investigated in the literature using several different approaches. In this study, a finite element (FE) model was used to simulate the dispersion curves of the modes propagating in an aluminum/adhesive/aluminum bonded structure. The simulated dispersion curves were systematically compared with the experimental measurements to retrieve the shear modulus of the adhesive layer during its curing process. The optimization procedure was able to perform inversion with minimum prior knowledge of the adhesive layer properties. In general, the proposed FE-based forward model was able to match the experimental dispersion curves during curing. Notwithstanding some discrepancies observed in the early to intermediate state of curing, the predicted model parameters were in agreement within 6% of the values obtained by the reference methods. The optimal shear modulus was estimated at 1.55 GPa at the end of the curing, against a reference value of 1.47 GPa.

Journal Title: IEEE Transactions on Ultrasonics, Ferroelectrics, and Frequency Control

Year Published: 2022

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!