Photo from wikipedia

Editor, The captioned letter alleges discrepancies between design and results reported in our recent study of the accuracy of conclusions by forensic firearms examiners [1, 2]. In summary, the correspondents… Click to show full abstract

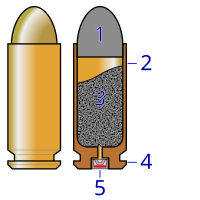

Editor, The captioned letter alleges discrepancies between design and results reported in our recent study of the accuracy of conclusions by forensic firearms examiners [1, 2]. In summary, the correspondents note that, while we designed and implemented the study to preclude elimination decisions based on class characteristics, many of the reported elimination decisions were informed by disagreement in class characteristics. The decisions reported by examiners are explainable by factors due to firearm manufacture and wear. Class characteristics are measurable features of design prior to manufacture that are common to a class of items, for example, caliber, number of lands and grooves, twist direction of rifling, or machining marks that are present throughout all of a production run (e.g., circular marks characteristic of a machine turning process) [3]. Every category of the AFTE Range of Conclusions qualifies usage of class characteristics by the adjective, discernible [4]. A highlevel assessment of class characteristics can be readily discernible when information such as caliber is in disagreement. Besides obvious class differences, manufacturing methods can generate measurable differences that are acceptable or unimportant to the manufacture and performance of a firearm, such as subclass. Subclass characteristics are consistent features not determined prior to manufacture that may arise on tool surfaces during a limited interval of manufacture or use [3]. As noted in our design paper, we intended to eliminate relevance of class characteristics by creating each comparison set using bullets or cartridge cases fired from the same make and model firearm [2]. This fact was not communicated to the examiners, however, and the reporting form they used offered options for them to amplify their basis for an elimination conclusion. If specified, differences could be noted as due to differences in individual characteristics, class characteristics, or both [2, appendix 5]. Table 1 shows the bases of Elimination conclusions reported for comparisons of cartridge case and bullet sets [1, supporting information]. While differences in individual characteristics predominate for both specimen types, class characteristics are invoked far more frequently for conclusions of cartridge case comparisons (32% vs. 1.6% for bullets). Several plausible explanations relate to differences in manufacture. Cartridge case sets were produced from Beretta and Jimenez firearms. In the Beretta, the breech face is integral to the slide, while the Jimenez breech face consists of a contractmanufactured bolt that is inserted into the frame during the casting of frames by a second outside company [2, 5]. It is quite possible that job lots of bolt inserts from different contractors became intermixed. Differences in class characteristics of cartridge cases fired from Jimenez pistols could result if some bolt inserts were produced using different machining processes used by different manufacturers or at different times. The letter details that Jimenez firearm #7 was responsible for about 25% of all eliminations invoking class characteristics. Notably, of the 11 Jimenez firearms in the study (all of which shared the same highlevel class characteristics), 10 were consecutively manufactured, while Jimenez #7 was sampled from the FBI reference collection, and hence, is of unknown provenance. Differences from the others are to be expected. Subclass characteristics may occur, then discontinue, during a relatively short period of manufacture. Relative to the Raven 0.25 pistol that uses the same type of subcontracted bolt inserts and production techniques as Jimenez, manufacturer George Jennings noted that a fine buildup of metal may become microwelded to the cutting

Journal Title: Journal of Forensic Sciences

Year Published: 2023

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!