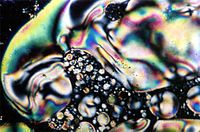

Photo from wikipedia

wileyonlinelibrary.com/journal/jace | 1293 © 2019 The American Ceramic Society 1 | INTRODUCTION Wing and Halloran1 exploited Raman spectroscopy to report residual stress relaxation of multiple GPa in silicon melt infiltrated… Click to show full abstract

wileyonlinelibrary.com/journal/jace | 1293 © 2019 The American Ceramic Society 1 | INTRODUCTION Wing and Halloran1 exploited Raman spectroscopy to report residual stress relaxation of multiple GPa in silicon melt infiltrated CMCs using high‐temperature thermal treatments. Other studies have used alternative means, such as X‐ray diffraction and curvature measurement, to determine residual stress relaxation in silicon at high temperatures.2‒4 The annealing time required to induce this relaxation is reported to be on the order of a few hours to a few seconds. For example, Wing and Halloran1 annealed a similar material to the one utilized in this study at 1200°C for 5 hours, reducing the measured residual stress by nearly 50% in the silicon phase, from 2.7 GPa to 1.4 GPa; however, minimal further change in the residual stress was observed after 75 hours of additional annealing at the same temperature. Interestingly, they also note that there was no evidence of complimentary changes in the residual stress state of other CMC constituents. In contrast, other tests performed within the semiconductor industry have shown that residual stresses initially present in silicon can relax up to 90% within timeframes of seconds or less at temperatures between 900 and 1300°C, although the stress magnitudes were within a few hundred MPa instead of the GPa stresses of the previous study.2‒4 Raman spectroscopy provides a simple and inexpensive method to determine residual stresses on a microscale Received: 12 January 2019 | Revised: 27 June 2019 | Accepted: 28 July 2019 DOI: 10.1111/jace.16724

Journal Title: Journal of the American Ceramic Society

Year Published: 2019

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!