Photo from wikipedia

The piezoelectric properties of lead zirconate titanate [Pb(Zr,Ti)O3 or PZT] ceramics could be enhanced by fabricating textured ceramics that would align the crystal grains along specific orientations. We present a… Click to show full abstract

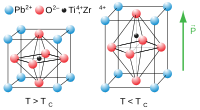

The piezoelectric properties of lead zirconate titanate [Pb(Zr,Ti)O3 or PZT] ceramics could be enhanced by fabricating textured ceramics that would align the crystal grains along specific orientations. We present a seed-passivated texturing process to fabricate textured PZT ceramics by using newly developed Ba(Zr,Ti)O3 microplatelet templates. This process not only ensures the template-induced grain growth in titanium-rich PZT layers but also facilitates desired composition through interlayer diffusion of zirconium and titanium. We successfully prepared textured PZT ceramics with outstanding properties, including Curie temperatures of 360°C, piezoelectric coefficients d33 of 760 picocoulombs per newton and g33 of 100 millivolt meters per newton, and electromechanical couplings k33 of 0.85. This study addresses the challenge of fabricating textured rhombohedral PZT ceramics by suppressing the otherwise severe chemical reaction between PZT powder and titanate templates. Description A winning template Lead zirconate titanate piezoelectrics are important for making transducers, sensors, and other components for electromechanical applications. To expand the usable temperature range and electromechanical coupling factor, Li et al. introduce a texturing process for lead zirconate titanate–based materials. A sacrificial template both changes the composition of the solid solution and orients the crystals to improve the piezoelectric properties. —BG A texturing process creates a lead zirconate titanate piezoelectric material with attractive properties.

Journal Title: Science

Year Published: 2023

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!