Photo from wikipedia

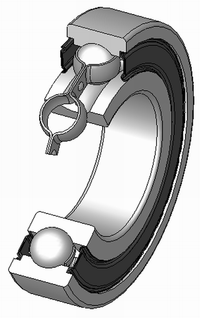

Fault diagnosis and failure prognostics for rolling element bearing are helpful for preventing equipment failure and predicting the remaining useful life (RUL) to avoid catastrophic failure. Spall size is an… Click to show full abstract

Fault diagnosis and failure prognostics for rolling element bearing are helpful for preventing equipment failure and predicting the remaining useful life (RUL) to avoid catastrophic failure. Spall size is an important fault feature for RUL prediction, and most research work has focused on estimating the fault size under constant speed conditions. However, estimation of the defect width under time-varying speed conditions is still a challenge. In this paper, a method is proposed to solve this problem. To enhance the entry and exit events, the edited cepstrum is used to remove the determined components. The preprocessed signal is resampled from the time domain to the angular domain to eliminate the effect of speed variation and measure the defect size of a rolling element bearing on outer race. Next, the transient impulse components are extracted by local mean decomposition. The entry and exit points when the roller passes over the defect width on the outer race were identified by further processing the extracted signal with time-frequency analysis based on the continuous wavelet transform. The defect size can be calculated with the angle duration, which is measured from the identified entry and exit points. The proposed method was validated experimentally.

Journal Title: Shock and Vibration

Year Published: 2019

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!