Photo from wikipedia

This paper presents a Hybrid Artificial Neural Network (HANN) for chiller system Measurement and Verification (M&V) model development. In this work, hybridization of Evolutionary Programming (EP) and Artificial Neural Network… Click to show full abstract

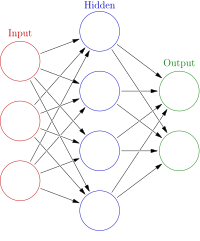

This paper presents a Hybrid Artificial Neural Network (HANN) for chiller system Measurement and Verification (M&V) model development. In this work, hybridization of Evolutionary Programming (EP) and Artificial Neural Network (ANN) are considered in modeling the baseline electrical energy consumption for a chiller system hence quantifying saving. EP with coefficient of correlation (R) objective function is used in optimizing the neural network training process and selecting the optimal values of ANN initial weights and biases. Three inputs that are affecting energy use of the chiller system are selected; 1) operating time, 2) refrigerant tonnage and 3) differential temperature. The output is hourly energy use of building air-conditioning system. The HANN model is simulated with 16 different structures and the results reveal that all HANN structures produce higher prediction performance with R is above 0.977. The best structure with the highest value of R is selected as the baseline model hence is used to determine the saving. The avoided energy calculated from this model is 132944.59 kWh that contributes to 1.38% of saving percentage.

Journal Title: Indonesian Journal of Electrical Engineering and Computer Science

Year Published: 2017

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!