Photo from wikipedia

In order to study the effect of microcrystalline cellulose on the reaction kinetics of polyurethane, in this work, the multi-scale microcrystalline cellulose was added to the foaming system of multifunctional… Click to show full abstract

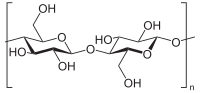

In order to study the effect of microcrystalline cellulose on the reaction kinetics of polyurethane, in this work, the multi-scale microcrystalline cellulose was added to the foaming system of multifunctional polyether and multifunctional MDI polyurethane. While the chemical reaction was carried out, it was found through in situ FTIR combined with in situ rheological analysis that what was different from the usual inorganic fillers, the hydroxyl on the surface of the microcrystalline cellulose could preferentially react with MDI to generate urethane under the action of the catalyst. In the initial 5–6 min of the reaction, the reaction of soft segment chain growth was the main reaction. Then the main reaction quickly converted to the cross-linking reaction, which greatly increased the viscosity of the system. The addition of microcrystalline celluloses accelerated the improvement of the cross-linking degree and viscosity of the system. The higher the surface hydroxyl content of microcrystalline cellulose, the more significant this trend become. In addition, although the amount of microcrystalline cellulose added was different, the ratio of the reaction rate of the isocyanate group with the hydroxyl group and the amine group eventually tended to be constant, which indicated that there was a stable reactivity rate in the gradual addition reaction during the cross-linking reaction. Combined with SEM analysis, it was found that 25–60 μm microcrystalline cellulose with large hydroxyl content could act as a nucleating agent when the addition amount was less than 0.1%, which was beneficial to increase the cell density and reduce the pore size and improved the impact performance of the foam. The microcrystalline cellulose with a length of more than 90 μm continuously penetrated through several cell walls and destroyed integrity of the cell structure, which would consequently reduce the impact strength of the foam. This paper provided theoretical guidance for polyurethane modified by microcrystalline cellulose.

Journal Title: Journal of Cellular Plastics

Year Published: 2022

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!