Photo from wikipedia

The present work focuses on the formulation of transient incompressible resin flow during vacuum-assisted resin transfer moulding using level set front tracking method in a multi-block structured grid within a… Click to show full abstract

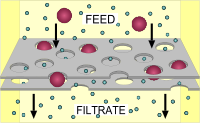

The present work focuses on the formulation of transient incompressible resin flow during vacuum-assisted resin transfer moulding using level set front tracking method in a multi-block structured grid within a finite difference framework. Initially, the relation between compaction pressure and fibre volume fraction ( V f ) has been established by conducting compression tests using a universal tensile machine under dry and wet conditions. In-plane permeability has been characterised as a function of V f using three thicknesses of unidirectional carbon fabric (4, 8 and 12 plies). A pressure data acquisition system and a non-contact out-of-plane displacement measurement setup have been developed using a single lens camera to conduct the vacuum infusion experiments. The numerical model prediction of the instantaneous change in pressure, displacement, and fill time has been validated with the experiments for the three different thickness of unidirectional preform in a flat plate and a plate with a centrally located hole during vacuum infusion. The coupled transient flow model with the level set interface propagation in a multi-block framework shows a good agreement with vacuum infusion experiments. The proposed transient vacuum infusion flow model, compaction relation with V f , permeability and experimental setup show the potential to capture realistic flow physics during vacuum infusion on different mould configurations.

Journal Title: Journal of Reinforced Plastics and Composites

Year Published: 2020

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!