Photo from wikipedia

To improve the curing properties of cyanate esters and retain their heat resistance, dielectric properties and adhesion properties, modified cyanate copolymers were prepared by blending bisphenol A cyanate (BADCy) ester… Click to show full abstract

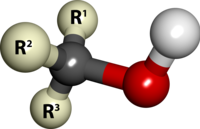

To improve the curing properties of cyanate esters and retain their heat resistance, dielectric properties and adhesion properties, modified cyanate copolymers were prepared by blending bisphenol A cyanate (BADCy) ester with phenol, hydroquinone (HO), resorcinol and phloroglucinol (LO). Differential scanning calorimetry analysis (DSC) and Fourier transform infrared spectroscopy were used to investigate the cure behaviours of the prepared compounds. The prepared materials were compared with the BADCy ester containing trace of cobalt acetylacetonate (CoAt). The CoAt/BADCy blend modified by HO exhibited better curing properties. The exothermic peak temperature (T p) of the CoAt/BADCy blend dropped to 169°C after introducing 1 wt% HO, likely due to the hydroxyl functional groups at the para position of the benzene ring resulting in higher symmetry and reactivity for the HO. In addition, compared with original CoAt/BADCy, the cyanate esters modified by phenolic hydroxyl groups demonstrated higher adhesive properties and a similar glass transition temperature (approximately 290°C) as well as stable dielectric properties. The experimental results indicate potential applications of the cyanate ester under high-temperature conditions.

Journal Title: High Performance Polymers

Year Published: 2020

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!