Photo from wikipedia

Fabrication methods for a 3D periodic nanostructure with excellent and unique properties for various applications, such as photonic and phononic crystals, have attracted considerable interest. Templating processes using colloidal crystals… Click to show full abstract

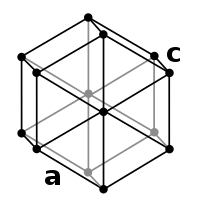

Fabrication methods for a 3D periodic nanostructure with excellent and unique properties for various applications, such as photonic and phononic crystals, have attracted considerable interest. Templating processes using colloidal crystals have been proposed to create nanoshell-based 3D structures over a large area with ease. However, there are technical limitations in structural design, resulting in difficulties for structural flexibility. Here, we demonstrate a combination of proximity field nanopatterning and infiltration processes using solution-derived ZnO for a nanoshell-based 3D periodic structure with high structural flexibility and controllability. A unique process of infiltration of a solution-derived material into a polymeric template prepared by a proximity field nanopatterning process achieves the fabrication of a pre-formed layer that works as a protective layer for the template and framework for the inverse structure. Subsequently, this process shows the controllability of nanoshell thickness and significant improvement in the structure height shrinkage factor (16%) compared to those of a previous non-vacuum infiltration method (34%). The proposed method offers high controllability and flexibility in the design of structural sizes, leading to further development toward nanoshell-based 3D structures for various applications including energy devices and sensors.

Journal Title: Nanoscale Research Letters

Year Published: 2017

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!