Photo from wikipedia

Sufficient biocompatibility and high strength are fundamental properties required for total joint endoprostheses material. Recently developed Ti-based alloy Ti–35.3Nb–7.3Zr–5.7Ta–0.7O (wt%) exhibits these properties. However, the as-cast material does not meet… Click to show full abstract

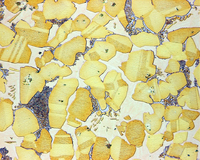

Sufficient biocompatibility and high strength are fundamental properties required for total joint endoprostheses material. Recently developed Ti-based alloy Ti–35.3Nb–7.3Zr–5.7Ta–0.7O (wt%) exhibits these properties. However, the as-cast material does not meet requirements for fatigue resistance due to pores and very coarse grain structure and therefore a feasible forming procedure must be established. Gleeble apparatus was used to deform the studied alloy at high temperatures (from 800 ◦C to 1400 ◦C) and high strain rates (up to 1 s−1) to the total strain of 0.5. Mechanical properties at elevated temperatures were evaluated. The resulting microstructure was investigated by scanning electron microscopy and electron backscatter diffraction (EBSD). It was found that forming procedure should be performed at temperatures higher than 1400 ◦C to reach conditions similar to forming of Ti–6Al–4V. Calculation of kernel average misorientation from EBSD data showed that most deformation is stored in the material in the vicinity of grain boundaries without any apparent recrystallization.

Journal Title: Acta Physica Polonica A

Year Published: 2018

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!