Photo from wikipedia

Manufacturing magnetoresistive random access memory (MRAM) requires the chemical mechanical polishing (CMP) of its bottom electrode, which is made of tantalum (Ta). The effect of ammonium citrate on the Ta… Click to show full abstract

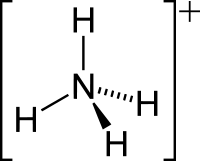

Manufacturing magnetoresistive random access memory (MRAM) requires the chemical mechanical polishing (CMP) of its bottom electrode, which is made of tantalum (Ta). The effect of ammonium citrate on the Ta removal rate (RR) and surface roughness of oxalic-acid-based slurries was investigated in this study. Additionally, the complexation mechanism of NH4 + and oxalic acid to Ta was explored by electrochemical experiments and X-ray photoelectron spectroscopy (XPS) analysis. According to the obtained findings, the RR and surface quality of Ta were improved with the addition of ammonium. The RRs of Ta and tetraethyl orthosilicate (TEOS) in the optimized slurry are 954 Å min^−1 and 242 Å min^−1, respectively. The root-mean-square (RMS) and peak-to-valley (P/V) of the Ta wafer after polishing reached 0.192 nm and 1.58 nm respectively by atomic force microscope (AFM). However, more detailed studies are needed to confirm the reproducibility of this initial observation, for using them for commercialization and use in industrial applications. Graphical abstract

Journal Title: Journal of Materials Research

Year Published: 2023

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!