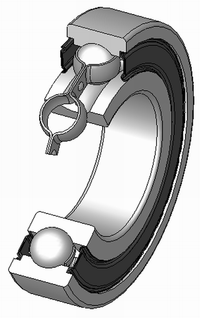

Photo from wikipedia

Increasing efforts to reduce frictional losses and the associated use of low-viscosity lubricants lead to machine elements being operated under mixed lubrication. Consequently, wear effects are also gaining relevance. Appropriate… Click to show full abstract

Increasing efforts to reduce frictional losses and the associated use of low-viscosity lubricants lead to machine elements being operated under mixed lubrication. Consequently, wear effects are also gaining relevance. Appropriate numerical modeling and predicting wear in a reliable manner offers new possibilities for identifying harmful operating conditions or for designing running-in procedures. However, most previous investigations focused on simplified model contacts and the wear behavior of application-oriented contacts is relatively underexplored. Therefore, the contribution of this paper was to provide a numerical procedure for studying the wear evolution in the mixed elastohydrodynamically lubricated (EHL) roller/raceway contact by coupling a finite element method (FEM)-based 3D EHL model with surface topography changes following a local Archard-type wear model, a Greenwood–Williamson-based load-sharing approach and the Sugimura surface adaption model. This study applied the operating conditions of an 81212 thrust roller bearing, considering realistic geometry and locally varying velocities. The calculated wear profiles in the raceway featured asymmetries, which were in good agreement with the experimental results reported in the literature and could be correlated with the velocity and slip distribution. In addition, the effects of speed, load and oil viscosity were investigated by means of four load cases and two lubricants, demonstrating the broad range of applying the numerical approach.

Journal Title: Lubricants

Year Published: 2020

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!