Photo from wikipedia

Apart from being used as an oil stock for bio-fuels production, an annual crop plant Brassica napus, thought to be an agro-waste, and used either as an animal feed, soil… Click to show full abstract

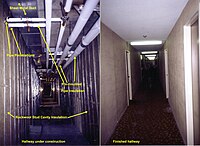

Apart from being used as an oil stock for bio-fuels production, an annual crop plant Brassica napus, thought to be an agro-waste, and used either as an animal feed, soil fertilizer or biomass for combustion and thermal energy production. Alternatively, as a bio-based and locally bio-sourced cellulosic material, it could be used as a thermal insulation in sustainable building fabrication, likewise woodchips, a bio-waste from the wood industry. In this study, the above-mentioned bio-waste materials’ thermal properties were identified using a sandwich panel from medium density fibreboard (MDF) and wood studs. Premanufactured panels have been filled in with randomly oriented short-cut rapeseed and with short-cut woodchips. A modified guarded hot box method was used to designate steady and un-steady state thermo-physical parameters of such insulation panels. The examined bio-waste materials absorbed thermal fluctuations of the exterior environment and kept the indoor building environment at constant temperature regardless of such fluctuations. The ability of bio-based sandwich panels to store heat energy was found to be similar to mineral wool. Additionally, VOC (volatile organic compound) emissions of tested materials were identified using gas chromatography-mass spectrometry (GC-MS) combined with headspace solid-phase microextraction (HS-SPME) to declare materials’ harmlessness to indoor environmental quality and human wellbeing. In conclusion, bio-based short-cut materials proved to be a viable environmentally friendly and energy efficient alternative to conventionally used thermal insulations.

Journal Title: Materials

Year Published: 2019

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!