Photo from wikipedia

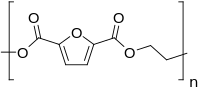

Using 2,5-furandicarboxylic acid, ethylene glycol, and poly(ethylene glycol) as raw materials and ethylene glycol antimony as a catalyst, poly(ethylene furandicarboxylate) (PEF) and polyethylene glycol (PEG) copolymers (PEGFs) were synthesized by… Click to show full abstract

Using 2,5-furandicarboxylic acid, ethylene glycol, and poly(ethylene glycol) as raw materials and ethylene glycol antimony as a catalyst, poly(ethylene furandicarboxylate) (PEF) and polyethylene glycol (PEG) copolymers (PEGFs) were synthesized by transesterification by changing the molecular weight of PEG (from 600 to 10,000 g/mol) and the PEG content (from 10 to 60 wt %). The thermal, hydrophilic, degradation, and spinnility characteristics of these copolymers were then investigated. Thermogravimetric analysis shows that PEGF is thermally stable at 62 °C, much lower than the temperature for PEF. The intrinsic viscosity of the obtained copolyester was between 0.67 and 0.99 dL/g, which is higher than the viscosity value of PEF. The contact angle experiment shows that the hydrophilicity of PEGFs is improved (the surface contact angle is reduced from 91.9 to 63.3°), which gives PEGFs a certain degradability, and the maximum mass loss can reach approximately 15%. Melt spinning experiments show that the PEGF polymer has poor spinnability, but the mechanical properties of the polymer monofilament are better.

Journal Title: Polymers

Year Published: 2019

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!