Photo from wikipedia

A novel computer optimization system for the contrary-rotating double-screw extrusion of plastics was developed in this study. The optimization was based on the process simulation performed with the use of… Click to show full abstract

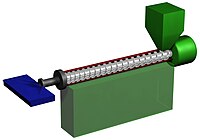

A novel computer optimization system for the contrary-rotating double-screw extrusion of plastics was developed in this study. The optimization was based on the process simulation performed with the use of the global contrary-rotating double-screw extrusion software TSEM. The process was optimized using the GASEOTWIN software developed for this purpose using genetic algorithms. Several examples of optimization of the contrary-rotating double screw extrusion process parameters, i.e., the extrusion throughput, and minimize the plastic melt temperature and the plastic melting length.

Journal Title: Polymers

Year Published: 2023

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!