Enhanced Ductility of a Bimodal Grain Structure Ti–22Al–25Nb Alloy Fabricated by Spark Plasma Sintering

Sign Up to like & getrecommendations! Published in 2017 at "Advanced Engineering Materials"

DOI: 10.1002/adem.201600804

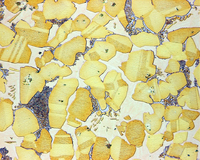

Abstract: A bimodal grain structure Ti–22Al–25Nb alloy with enhanced ductility is fabricated from the blended powder mixture of argon gas atomized powder and mechanically alloyed powder by spark plasma sintering. The microstructure of the bimodal grain… read more here.

Keywords: alloy; bimodal grain; powder; 25nb alloy ... See more keywords

Deformation Behavior and Dynamic Recrystallization of Ti–22Al–25Nb Alloy at 750–990 °C

Sign Up to like & getrecommendations! Published in 2019 at "Advanced Engineering Materials"

DOI: 10.1002/adem.201901231

Abstract: Ti–22Al–25Nb is a representative of Ti2AlNb alloys with excellent comprehensive properties, which has great application prospects in the aerospace field. Herein, high‐temperature tensile plastic deformation behavior and dynamic recrystallization process of Ti–22Al–25Nb alloy are researched… read more here.

Keywords: 22al 25nb; dynamic recrystallization; deformation behavior; alloy ... See more keywords

Microstructural Evolution and Mechanical Properties of Ti-22Al-25Nb (At.%) Orthorhombic Alloy with Three Typical Microstructures

Sign Up to like & getrecommendations! Published in 2017 at "Journal of Materials Engineering and Performance"

DOI: 10.1007/s11665-017-3040-9

Abstract: Microstructural evolution, tensile and creep behavior of Ti-22Al-25Nb (at.%) orthorhombic alloy with three typical microstructures were investigated. The three typical microstructures were obtained by different solution and age treatment temperatures and analyzed by the BSE… read more here.

Keywords: alloy; microstructural evolution; 25nb orthorhombic; typical microstructures ... See more keywords

Selective laser melting enabled additive manufacturing of Ti–22Al–25Nb intermetallic: Excellent combination of strength and ductility, and unique microstructural features associated

Sign Up to like & getrecommendations! Published in 2019 at "Acta Materialia"

DOI: 10.1016/j.actamat.2019.05.008

Abstract: Abstract To realize near net-shaping of hard-to-process intermetallics is an often challenging but critical issue to their wider industrial applications. In this work, we report that an intermetallic Ti–22Al–25Nb has been successfully fabricated by selective… read more here.

Keywords: ductility; 22al 25nb; strength; selective laser ... See more keywords

WITHDRAWN: Characterization of the hot deformation behaviour of powder metallurgy Ti–22Al–25Nb alloy by using 3D processing maps

Sign Up to like & getrecommendations! Published in 2020 at "Intermetallics"

DOI: 10.1016/j.intermet.2020.106776

Abstract: Abstract Powder metallurgy (PM) Ti–22Al–25Nb (at.%) alloy was prepared by spark plasma sintering under the conditions of 950 °C/80 MPa/10 min. Isothermal unidirectional compression experiments of the PM Ti–22Al–25Nb alloy were completed on the Gleeble-3500 thermal–mechanical simulator… read more here.

Keywords: deformation; metallurgy; processing maps; 25nb alloy ... See more keywords

Microstructure and mechanical properties of a Ti−22Al−25Nb alloy fabricated from elemental powders by mechanical alloying and spark plasma sintering

Sign Up to like & getrecommendations! Published in 2017 at "Journal of Alloys and Compounds"

DOI: 10.1016/j.jallcom.2017.01.354

Abstract: Abstract This study deals with the fabrication of a fine-grained Ti−22Al−25Nb alloy from elemental powders by mechanical alloying (MA) and subsequent spark plasma sintering (SPS). The effect of SPS parameters on the microstructure and mechanical… read more here.

Keywords: elemental powders; mechanical properties; 25nb alloy; powders mechanical ... See more keywords

Microstructure and mechanical properties of ultrasonic pulse frequency tungsten inert gas welded Ti-22Al-25Nb (at.%) alloy butt joint

Sign Up to like & getrecommendations! Published in 2018 at "Journal of Materials Processing Technology"

DOI: 10.1016/j.jmatprotec.2018.03.018

Abstract: Abstract Microstructural observations of cross sections of butt joints of Ti-22Al-25Nb (at.%) alloy manufactured using ultrasonic pulse frequency tungsten inert gas welding method at different welding parameters without and with welding wire, the butt joint… read more here.

Keywords: butt; butt joint; pulse frequency; 25nb alloy ... See more keywords

Selective laser melting of Ti–22Al–25Nb intermetallic: Significant effects of hatch distance on microstructural features and mechanical properties

Sign Up to like & getrecommendations! Published in 2020 at "Journal of Materials Processing Technology"

DOI: 10.1016/j.jmatprotec.2019.116398

Abstract: Abstract Ti–22Al–25Nb (at.%) intermetallic is a light weight, high performance, high temperature material with density of merely ˜60% of Ni-based superalloys. The advent and rapid development of selective laser melting (SLM) enable direct fabrication of… read more here.

Keywords: selective laser; 25nb intermetallic; mechanical properties; hatch distance ... See more keywords

Microstructure evolution and phase transformations in Ti-22Al-25Nb alloys tailored by super-transus solution treatment

Sign Up to like & getrecommendations! Published in 2019 at "Vacuum"

DOI: 10.1016/j.vacuum.2018.12.044

Abstract: Abstract The decomposition of metastable β phase and microstructural evolution of a forged Ti-22Al-25Nb orthorhombic alloys were investigated by the electron microscopes and phase identification. For the near-Ti2AlNb alloy, the processing temperatures were super-transus (over… read more here.

Keywords: super transus; phase; 22al 25nb; microstructure evolution ... See more keywords

Microstructure and mechanical properties of Ti-6Al-4V/Ti-22Al-25Nb joint formed by diffusion bonding

Sign Up to like & getrecommendations! Published in 2021 at "Transactions of Nonferrous Metals Society of China"

DOI: 10.1016/s1003-6326(21)65581-4

Abstract: Abstract Ti-6Al-4V (wt.%) and Ti-22Al-25Nb (at.%) were joined by diffusion bonding at 950 °C and 15 MPa for 100 min, and the microstructure and mechanical properties of the resulting joints were investigated. The composition of… read more here.

Keywords: microstructure mechanical; mechanical properties; diffusion bonding; 22al 25nb ... See more keywords