Effect of electrochemical charging on the hydrogen embrittlement susceptibility of alloy 718

Sign Up to like & getrecommendations! Published in 2019 at "Acta Materialia"

DOI: 10.1016/j.actamat.2019.08.020

Abstract: Abstract The susceptibility of age-hardened nickel-based Alloy 718 to hydrogen embrittlement was studied by the controlled electrochemical charging combined with slow strain-rate tensile tests (SSRT) and advanced characterization techniques. We proposed some novel ideas of… read more here.

Keywords: susceptibility; hydrogen; alloy 718; electrochemical charging ... See more keywords

Effect of post-treatments under hot isostatic pressure on microstructural characteristics of EBM-built Alloy 718

Sign Up to like & getrecommendations! Published in 2019 at "Additive Manufacturing"

DOI: 10.1016/j.addma.2019.06.002

Abstract: Electron beam melting (EBM) has emerged as an important additive manufacturing technique. In this study, Alloy 718 produced by EBM was investigated in as-built and post-treated conditions for microstructural characteristics and hardness. The post-treatments investigated… read more here.

Keywords: post; alloy 718; post treatments; microstructural characteristics ... See more keywords

FE modeling and simulation of machining Alloy 718 based on ductile continuum damage

Sign Up to like & getrecommendations! Published in 2020 at "International Journal of Mechanical Sciences"

DOI: 10.1016/j.ijmecsci.2019.105375

Abstract: A novel model for rigid visco-plastic flow and continuous damage evolution is proposed for the modeling and simulation of chip formation of the alloy 718. The model draws from a recent thermodynamically consistent damage coupled… read more here.

Keywords: modeling simulation; chip formation; alloy 718; model ... See more keywords

Metallurgical effects of nitrogen on the microstructure and hot corrosion behavior of Alloy 718 weldment

Sign Up to like & getrecommendations! Published in 2019 at "Materials Characterization"

DOI: 10.1016/j.matchar.2019.109916

Abstract: Abstract The effects of nitrogen added by autogenous gas tungsten arc (GTA) welding on weld microstructure and hot corrosion resistance of Alloy 718 exposed to Na2SO4–25%wt NaCl salt compound at 650 °C have been studied. The… read more here.

Keywords: hot corrosion; microscopy; alloy 718; corrosion ... See more keywords

Investigation of laser metal deposited Alloy 718 onto an EN 1.4401 stainless steel substrate

Sign Up to like & getrecommendations! Published in 2017 at "Optics and Laser Technology"

DOI: 10.1016/j.optlastec.2017.05.038

Abstract: Abstract This paper focuses on how process parameters affect the deposition of Alloy 718 onto an EN 1.4401 stainless steel substrate in terms of secondary phase formation, dilution and hardness. A columnar solidification structure with… read more here.

Keywords: onto 4401; 718 onto; 4401 stainless; alloy 718 ... See more keywords

Effects of high-pressure cooling in the flank and rake faces of WC tool on the tool wear mechanism and process conditions in turning of alloy 718

Sign Up to like & getrecommendations! Published in 2019 at "Wear"

DOI: 10.1016/j.wear.2019.05.037

Abstract: The exceptional properties of Heat Resistant Super Alloys (HRSA) justify the search for advanced technologies that can improve the capability of machining these materials. One such advanced technology is the application of a coolant at… read more here.

Keywords: high pressure; alloy 718; wear mechanism; pressure ... See more keywords

Effect of vanadium content on as-cast micro-structure and mechanical properties of alloy 718

Sign Up to like & getrecommendations! Published in 2019 at "Materials Research Express"

DOI: 10.1088/2053-1591/ab109a

Abstract: Effect of limited amounts of vanadium from 0.081 to 1.88 wt% on the micro-structure and mechanical properties in alloy 718 is evaluated. Corresponding morphology, constituent and structure are measured by metallurgical microscope, energy dispersive spectrum,… read more here.

Keywords: mechanical properties; alloy 718; micro structure; structure ... See more keywords

Increase in Strength and Fretting Resistance of Alloy 718 Using the Surface Modification Process

Sign Up to like & getrecommendations! Published in 2018 at "Materials"

DOI: 10.3390/ma11081366

Abstract: This work comparatively investigated the strength (hardness, yield strength, dynamic elastic modulus, and surface residual stress), fretting failure, and corrosion resistance of the as-received and treated Ni-based superalloy Alloy 718. The goal of the current… read more here.

Keywords: strength; surface; alloy 718; process ... See more keywords

Effect of the Process Atmosphere Composition on Alloy 718 Produced by Laser Powder Bed Fusion

Sign Up to like & getrecommendations! Published in 2021 at "Metals"

DOI: 10.3390/met11081254

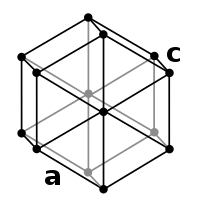

Abstract: The detrimental effect of nitrogen and oxygen when it comes to the precipitation of the strengthening γ’’ and γ’ phases in Alloy 718 is well-known from traditional manufacturing. Hence, the influence of the two processing… read more here.

Keywords: nitrogen; powder bed; alloy 718; powder ... See more keywords

Comparison of Hot Cracking Susceptibility of TIG and Laser Beam Welded Alloy 718 by Varestraint Testing

Sign Up to like & getrecommendations! Published in 2019 at "Metals"

DOI: 10.3390/met9090985

Abstract: Reduced hot cracking susceptibility is essential to ensure the flawless manufacturing of nickel superalloys typically employed in welded aircraft engine structures. The hot cracking of precipitation strengthened alloy 718 mainly depends on chemical composition and… read more here.

Keywords: laser beam; hot cracking; alloy 718; varestraint ... See more keywords