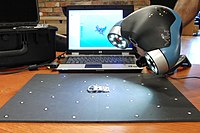

Cutting parameters optimization for MRR under the constraints of surface roughness and cutter breakage in micro-milling process

Sign Up to like & getrecommendations! Published in 2018 at "Journal of Mechanical Science and Technology"

DOI: 10.1007/s12206-018-0641-7

Abstract: Selection of cutting parameters in micro-milling operations is essential for improving machining efficiency and quality, and prolonging the micro-milling tool life. The increase of material removal rate (MRR) always means the increase of cutting parameters,… read more here.

Keywords: mrr; cutting parameters; surface roughness; micro milling ... See more keywords

FEM simulation-based cutting parameters optimization in machining aluminum-silicon piston alloy ZL109 with PCD tool

Sign Up to like & getrecommendations! Published in 2019 at "Journal of Mechanical Science and Technology"

DOI: 10.1007/s12206-019-0640-3

Abstract: The Johnson-Cook (JC) constitutive model was utilized to simulate the processing of Al-Si piston alloy ZL109 to obtain the optimal finishing parameters in polycrystalline diamond (PCD) tool, and studied the machining quality of ordinary-turning under… read more here.

Keywords: alloy zl109; cutting parameters; residual stress; piston alloy ... See more keywords

Study of the influence of cutting parameters on surface quality in AWJM machining of thermoplastic matrix composites

Sign Up to like & getrecommendations! Published in 2019 at "Procedia Manufacturing"

DOI: 10.1016/j.promfg.2019.07.051

Abstract: Abstract The application of Carbon Fiber Reinforced ThermoPlastic matrix composites (CFRTP) is constantly increasing today. They have an excellent weight-to-mechanical properties ratio and in comparison to thermostable matrix composites their recycling efficiency is higher. However,… read more here.

Keywords: thermoplastic matrix; quality; surface quality; cutting parameters ... See more keywords

An integrated decision-making approach on cutting tools and cutting parameters for machining features considering carbon emissions

Sign Up to like & getrecommendations! Published in 2019 at "International Journal of Computer Integrated Manufacturing"

DOI: 10.1080/0951192x.2019.1610575

Abstract: ABSTRACT Cutting parameters and cutting tools are vital in process planning. Reasonable decision-making of cutting parameters and cutting tools could reduce the processing carbon emissions, time, and cost in machining process. Traditionally, cutting parameter optimization… read more here.

Keywords: cutting tools; methodology; cutting parameters; carbon emissions ... See more keywords

Simultaneous optimization of fixture and cutting parameters of thin-walled workpieces based on particle swarm optimization algorithm

Sign Up to like & getrecommendations! Published in 2018 at "SIMULATION"

DOI: 10.1177/0037549717713850

Abstract: The elastic deformation of thin-walled workpieces is because of the combination effect of cutting force and clamping force, which also leads to processing error. Clamping force and cutting force have coupling effect during this process.… read more here.

Keywords: cutting parameters; fixture cutting; thin walled; optimization ... See more keywords

Effects of Process Cutting Parameters on the Ti-6Al-4V Turning with Monolithic Driven Rotary Tool

Sign Up to like & getrecommendations! Published in 2022 at "Materials"

DOI: 10.3390/ma15155181

Abstract: Machining with rotating tools appears to be an efficient method that employs a non-standard kinematic turning scheme. It is used in the machining of materials that we classify in the category of difficult to machine.… read more here.

Keywords: rotary tool; cutting parameters; driven rotary; monolithic driven ... See more keywords

Effect of Drilling Parameters on Machining Performance in Drilling Polytetrafluoroethylene

Sign Up to like & getrecommendations! Published in 2022 at "Materials"

DOI: 10.3390/ma15196922

Abstract: Polytetrafluoroethylene (PTFE) plays an important role in semiconductor manufacturing. It is an important processing material for the key sealing components in the field of immersion lithography. The lack of research related to the mechanical processing… read more here.

Keywords: ptfe; effect; cutting parameters; drilling performance ... See more keywords

Effects of Laser Cutting Parameters on the Magnetic Properties of 50W350 High-Grade Non-Oriented Electrical Steel

Sign Up to like & getrecommendations! Published in 2023 at "Materials"

DOI: 10.3390/ma16041642

Abstract: Based on the application demand of laser cutting technology in non-oriented electrical steel, the influencing mechanisms of laser cutting parameters on the magnetic properties of 50W350 high-grade non-oriented electrical steel were investigated in this work.… read more here.

Keywords: laser cutting; oriented electrical; cutting parameters; non oriented ... See more keywords

Force Prediction and Cutting-Parameter Optimization in Micro-Milling Al7075-T6 Based on Response Surface Method

Sign Up to like & getrecommendations! Published in 2020 at "Micromachines"

DOI: 10.3390/mi11080766

Abstract: Optimization of cutting parameters in micro-milling is an important measure to improve surface quality and machining efficiency of the workpiece. Investigation of micro-milling forces prediction plays a positive role in improving machining capacity. To predict… read more here.

Keywords: response; cutting parameters; surface; micro milling ... See more keywords