Superplasticity and Micro-arrayed Deep-Drawing Behavior of Ni-Co/GO Nanocomposite

Sign Up to like & getrecommendations! Published in 2017 at "Journal of Materials Engineering and Performance"

DOI: 10.1007/s11665-017-2924-z

Abstract: In this article, Ni-Co/GO nanocomposite was fabricated by AC pulse electrodeposition method. The room temperature strength tests and the superplasticity of the nanocomposite were investigated by the tensile tests. A 5 × 5 micro-arrayed deep-drawing die was… read more here.

Keywords: deep drawing; drawing; superplasticity; arrayed deep ... See more keywords

Phase-specific residual stresses induced by deep drawing of lean duplex steel: measurement vs. simulation

Sign Up to like & getrecommendations! Published in 2019 at "Production Engineering"

DOI: 10.1007/s11740-019-00877-4

Abstract: The final geometry and fatigue behavior of deep drawn components in service is strongly influenced by deformation-induced residual stresses. For multi-phase materials, besides macro residual stresses (first kind), phase-specific residual stresses (second kind) occur on… read more here.

Keywords: deep drawing; specific residual; phase specific; residual stresses ... See more keywords

Twist springback characteristics of dual-phase steel sheet after non-axisymmetric deep drawing

Sign Up to like & getrecommendations! Published in 2017 at "International Journal of Material Forming"

DOI: 10.1007/s12289-015-1275-2

Abstract: This paper aims to investigate the twist springback characteristics of advanced high strength steel sheet subjected to deep drawing. A C-rail benchmark, which leads to a particularly pronounced twist springback characteristics, was developed. For an… read more here.

Keywords: twist springback; springback characteristics; deep drawing; springback ... See more keywords

Deep drawing behavior of twinning-induced plasticity-cored three-layer steel sheet

Sign Up to like & getrecommendations! Published in 2018 at "International Journal of Material Forming"

DOI: 10.1007/s12289-016-1324-5

Abstract: Herein, we report the results of our experimental and computational investigation of the deep drawing behavior of twinning-induced plasticity (TWIP)-cored three-layer steel sheet. Various directional tensile tests for monolayer sheets of the TWIP and low-carbon… read more here.

Keywords: steel sheet; steel; deep drawing; three layer ... See more keywords

Analysis of non-isothermal warm deep drawing of dual-phase DP600 steel

Sign Up to like & getrecommendations! Published in 2019 at "International Journal of Material Forming"

DOI: 10.1007/s12289-018-1400-0

Abstract: Improving the formability of the material is a key issue in the deep drawing process. Heating the material above its recrystallization temperature drastically increases formability, but in the case of dual phase (DP) steels, it… read more here.

Keywords: steel; experimental results; deep drawing; dual phase ... See more keywords

Optimization of multi-objective quality of TWBs square box deep-drawing process parameters

Sign Up to like & getrecommendations! Published in 2019 at "Journal of the Brazilian Society of Mechanical Sciences and Engineering"

DOI: 10.1007/s40430-019-1673-3

Abstract: There are many process parameters involved in the deep drawing of TWBs. Each parameter has different effects on the forming quality and intercrosses each other. It is difficult to establish the relationship between the process… read more here.

Keywords: twbs square; quality; deep drawing; square box ... See more keywords

Effect of friction stir welding parameters on the deep drawing of tailor-welded blanks (TWBs)

Sign Up to like & getrecommendations! Published in 2021 at "Cirp Journal of Manufacturing Science and Technology"

DOI: 10.1016/j.cirpj.2021.02.011

Abstract: Abstract Friction stir welding is a method for joining dissimilar sheets and producing tailor-welded blanks (TWBs). An important issue in TWBs is their formability, as the material properties is not uniform across the welding line.… read more here.

Keywords: deep drawing; welded blanks; friction stir; friction ... See more keywords

Deep drawing simulations using the finite element method embedding a multi-level crystal plasticity constitutive law: Experimental verification and sensitivity analysis

Sign Up to like & getrecommendations! Published in 2019 at "Computer Methods in Applied Mechanics and Engineering"

DOI: 10.1016/j.cma.2019.05.035

Abstract: Abstract This paper presents experimental verification of a multi-level simulation framework aimed at sheet metal forming analysis. Specifically, deep drawing of a cylindrical cup simulations from alloy AA6022-T4 sheets are carried out using a physically… read more here.

Keywords: deep drawing; level; cup; experimental verification ... See more keywords

Deep drawing of fiber metal laminates for automotive lightweight structures

Sign Up to like & getrecommendations! Published in 2019 at "Composite Structures"

DOI: 10.1016/j.compstruct.2019.02.047

Abstract: Abstract Current challenges in the automotive industry are the reduction of fuel consumption and the CO2 emissions of future car generations. These aims can be achieved by reducing the weight of the car, which further… read more here.

Keywords: structures deep; deep drawing; fiber metal; metal laminates ... See more keywords

Trajectory planning and tracking control for the temperature distribution in a deep drawing tool

Sign Up to like & getrecommendations! Published in 2017 at "Control Engineering Practice"

DOI: 10.1016/j.conengprac.2017.04.004

Abstract: Abstract The deep drawing process and the resulting product quality essentially rely on the temperature distribution inside the tool. For temperature manipulation and control a flatness-based design technique for thermal trajectory planning and feedforward control… read more here.

Keywords: deep drawing; temperature; control; trajectory planning ... See more keywords

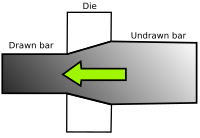

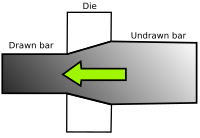

Performance evaluation of analytical expressions for cylindrical and rectangular deep drawing force estimation

Sign Up to like & getrecommendations! Published in 2018 at "Journal of Manufacturing Processes"

DOI: 10.1016/j.jmapro.2018.10.033

Abstract: Abstract The deep drawing force (DDF) is defined as the maximum force required to perform a given deep drawing operation. The DDF is needed to design the drawing tools, to define the press capacity and… read more here.

Keywords: deep drawing; cylindrical rectangular; rectangular parts; force ... See more keywords