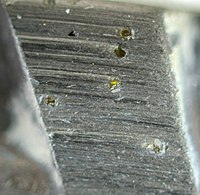

Experimental analysis of surface integrity of cemented carbides resulting from contemporary sinking EDM technology

Sign Up to like & getrecommendations! Published in 2019 at "Production Engineering"

DOI: 10.1007/s11740-019-00896-1

Abstract: The generator technology of electrical discharge machining (EDM) has evolved significantly over the last decades. This enabled EDM to become a crucial technology in die and mold manufacturing. Moreover, EDM became a more important technology… read more here.

Keywords: sinking edm; cemented carbides; edm technology; technology ... See more keywords

Micro-scale measurement & FEM modelling of residual stresses in AA6082-T6 Al alloy generated by wire EDM cutting

Sign Up to like & getrecommendations! Published in 2020 at "Journal of Materials Processing Technology"

DOI: 10.1016/j.jmatprotec.2019.116373

Abstract: Abstract Wire EDM is well-known as a technique for sectioning metallic samples that causes minimal disturbance in terms of residual stress introduction and modification at the macro-scale. Indeed, at the millimetre scale, EDM-induced residual stress… read more here.

Keywords: residual stress; edm; wire edm; residual stresses ... See more keywords

Effect of deep cryotreated tungsten carbide electrode and SiC powder on EDM performance of AISI 304

Sign Up to like & getrecommendations! Published in 2019 at "Particulate Science and Technology"

DOI: 10.1080/02726351.2018.1487491

Abstract: Abstract Powder mixed electric discharge machining (PMEDM) is a further advancement of conventional EDM process in which electrically conductive powder is suspended in the dielectric fluid to enhance the material removal rate (MRR) along with… read more here.

Keywords: edm; aisi 304; powder; electrode ... See more keywords

An environmental-friendly electrical discharge machining using different sustainable techniques: a review

Sign Up to like & getrecommendations! Published in 2020 at "Advances in Materials and Processing Technologies"

DOI: 10.1080/2374068x.2020.1785210

Abstract: ABSTRACT Electrical discharge machining (EDM) is one of the most broadly used non-traditional machining processes. The introduction of the idea of sustainable production and the need to adjust the ISO norms are essential for the… read more here.

Keywords: environmental friendly; discharge machining; edm; electrical discharge ... See more keywords

Scalar-pseudoscalar interaction in the francium atom

Sign Up to like & getrecommendations! Published in 2017 at "Physical Review A"

DOI: 10.1103/physreva.95.022507

Abstract: Fr atom can be successively used to search for the atomic permanent electric dipole moment (EDM) [Hyperfine Interactions 236, 53 (2015); Journal of Physics: Conference Series 691, 012017 (2016)]. It can be induced by the… read more here.

Keywords: atom; edm; scalar pseudoscalar; pseudoscalar interaction ... See more keywords

A novel servo-stabilized electromagnetic levitation formicro-EDM processing and its feasibility analysis

Sign Up to like & getrecommendations! Published in 2022 at "Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture"

DOI: 10.1177/09544054221124473

Abstract: The purpose of this paper is to evaluate the feasibility of a novel gap-controlled strategy for micro-EDM process using magnetic levitation. The tool is levitated and positioned accurately using a unique actuator arm. The actuator… read more here.

Keywords: feasibility; analysis; servo stabilized; edm ... See more keywords

Design of Real-Time Extremum-Seeking Controller-Based Modelling for Optimizing MRR in Low Power EDM

Sign Up to like & getrecommendations! Published in 2023 at "Materials"

DOI: 10.3390/ma16010434

Abstract: Electric discharge machining (EDM) is one of the non-conventional machining processes that supports machining for high-strength and wear-resistant materials. It is a challenging task to select the process parameters in real-time to maximize the material… read more here.

Keywords: time; extremum seeking; seeking controller; real time ... See more keywords

Research on Electrostatic Field-Induced Discharge Energy in Conventional Micro EDM

Sign Up to like & getrecommendations! Published in 2023 at "Materials"

DOI: 10.3390/ma16113963

Abstract: The electrostatic field-induced electrolyte jet (E-Jet) electric discharge machining (EDM) is a newly developed micro machining method. However, the strong coupling of the electrolyte jet liquid electrode and the electrostatic induced energy prohibited it from… read more here.

Keywords: field induced; energy; electrostatic field; discharge ... See more keywords

Parameters Optimization of Electrical Discharge Machining Process Using Swarm Intelligence: A Review

Sign Up to like & getrecommendations! Published in 2023 at "Metals"

DOI: 10.3390/met13050839

Abstract: Electrical discharge machining (EDM) can use soft tool electrodes to process hard workpieces to achieve “soft against hard”, because it directly uses electrical energy and thermal energy to remove metal materials. Then, it can generate… read more here.

Keywords: electrical discharge; discharge machining; edm; process parameters ... See more keywords

Suggested Research Trends in the Area of Micro-EDM—Study of Some Parameters Affecting Micro-EDM

Sign Up to like & getrecommendations! Published in 2021 at "Micromachines"

DOI: 10.3390/mi12101184

Abstract: This paper provides an overall view of the current research in micro-electrical discharge machining (micro-EDM or µEDM) and looks into the present understanding of the material removing mechanism and the common approach for electrode material… read more here.

Keywords: suggested research; micro edm; edm; research trends ... See more keywords