Cutting parameters optimization for MRR under the constraints of surface roughness and cutter breakage in micro-milling process

Sign Up to like & getrecommendations! Published in 2018 at "Journal of Mechanical Science and Technology"

DOI: 10.1007/s12206-018-0641-7

Abstract: Selection of cutting parameters in micro-milling operations is essential for improving machining efficiency and quality, and prolonging the micro-milling tool life. The increase of material removal rate (MRR) always means the increase of cutting parameters,… read more here.

Keywords: mrr; cutting parameters; surface roughness; micro milling ... See more keywords

Investigation on Micro-milling of Ti–6Al–4V Alloy by PCD Slotting-Tools

Sign Up to like & getrecommendations! Published in 2019 at "International Journal of Precision Engineering and Manufacturing"

DOI: 10.1007/s12541-019-00247-1

Abstract: Ti–6Al–4V is characterized by various protruding characteristics and has been found extensive applications in aerospace, biomedical device industries and other fields. However, these properties in turn bring about the increase in cutting forces, make the… read more here.

Keywords: micro milling; slotting tools; pcd; milling 6al ... See more keywords

Fabrication of CVD diamond micro-milling tool by hybrid machining of laser-induced graphitization and precision grinding

Sign Up to like & getrecommendations! Published in 2019 at "Ceramics International"

DOI: 10.1016/j.ceramint.2019.08.121

Abstract: Abstract Owing to exceptional hardness and wear resistance, Chemical Vapor Deposition (CVD) diamond material is broadly used for micro-milling tools. However, the fabrication of CVD diamond micro-milling tool by a traditional grinding process is less… read more here.

Keywords: cvd diamond; micro milling; diamond micro; milling tool ... See more keywords

Fabrication and performance of CVD diamond cutting tool in micro milling of oxygen-free copper

Sign Up to like & getrecommendations! Published in 2019 at "Diamond and Related Materials"

DOI: 10.1016/j.diamond.2019.107589

Abstract: Abstract Chemical vapor deposited (CVD) diamond is a promising material to fabricate micro-cutting tools owing to its ultra-high hardness, Young's modulus, and isotropic characteristics. In this research work, a novel compound process of laser-induced graphitization… read more here.

Keywords: micro milling; tool; cvd diamond; diamond ... See more keywords

Progressive wear based tool failure analysis during dry and MQL assisted sustainable micro-milling

Sign Up to like & getrecommendations! Published in 2021 at "International Journal of Mechanical Sciences"

DOI: 10.1016/j.ijmecsci.2021.106844

Abstract: Abstract Micro-milling tools suffer high wear rate and early edge-chipping owing to their small sizes. Mechanism of various wear modes of a coated tool with the progression of micro-milling along with the conditions for their… read more here.

Keywords: analysis; micro milling; edge; wear ... See more keywords

An innovative investigation on chip formation mechanisms in micro-milling using natural diamond and tungsten carbide tools

Sign Up to like & getrecommendations! Published in 2018 at "Journal of Manufacturing Processes"

DOI: 10.1016/j.jmapro.2017.11.023

Abstract: Abstract This paper presents an analytical approach to investigating the chip formation process in micro-milling aluminum 6082-T6 particularly by using natural diamond and tungsten carbide tools. Through well-designed micro-milling experiments, a comparative study is conducted… read more here.

Keywords: chip formation; natural diamond; micro milling; diamond ... See more keywords

On the correlation between surface quality and tool wear in micro–milling of pure copper

Sign Up to like & getrecommendations! Published in 2020 at "Journal of Manufacturing Processes"

DOI: 10.1016/j.jmapro.2020.01.015

Abstract: Abstract Micro-milling is a material removal – based manufacturing technique that allows fabrication of three-dimensional features in a direct manner, unlike photolithography which relies on expensive masks to print two-dimensional features onto a substrate. However,… read more here.

Keywords: surface quality; surface; micro milling; tool wear ... See more keywords

Tool wear and remaining useful life prediction in micro-milling along complex tool paths using neural networks

Sign Up to like & getrecommendations! Published in 2021 at "Journal of Manufacturing Processes"

DOI: 10.1016/j.jmapro.2021.09.055

Abstract: Abstract Monitoring tool wear state and prediction of the remaining useful life in micro-milling help avoid down time due to unalarmed failure of the cutting tool. In this regard, investigations based on experiments, and data-based… read more here.

Keywords: tool wear; micro milling; tool; useful life ... See more keywords

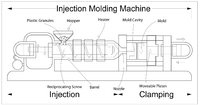

Impact of deep cores surface topography generated by micro milling on the demolding force in micro injection molding

Sign Up to like & getrecommendations! Published in 2017 at "Journal of Materials Processing Technology"

DOI: 10.1016/j.jmatprotec.2017.03.028

Abstract: Abstract In micro injection molding the quality of 3D complex parts is influenced by the efficiency of the ejection phase. During demolding, the forces taking place at the component-tool interface, due to adhesion and friction,… read more here.

Keywords: topography; micro milling; micro injection; injection molding ... See more keywords

Development and validation of a meshless 3D material point method for simulating the micro-milling process

Sign Up to like & getrecommendations! Published in 2018 at "Journal of Materials Processing Technology"

DOI: 10.1016/j.jmatprotec.2018.07.013

Abstract: Abstract A meshless generalized interpolation material point method for simulating the micro-milling process was developed. This method has several advantages over well-established approaches (such as finite elements) when it comes to large plastic strains and… read more here.

Keywords: micro milling; simulating micro; meshless; milling process ... See more keywords

Deflection prediction of micro-milling Inconel 718 thin-walled parts

Sign Up to like & getrecommendations! Published in 2021 at "Journal of Materials Processing Technology"

DOI: 10.1016/j.jmatprotec.2020.117003

Abstract: Abstract In the interest of lowering form factors and increasing specific strengths, there has been a great increase in the applications of micro thin-walled parts in many fields, such as medical devices, aerospace and so… read more here.

Keywords: inconel 718; deflection; walled parts; micro milling ... See more keywords