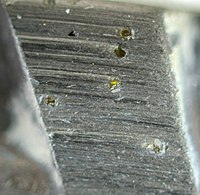

Effect of repeated millings on the surface integrity of diamond burs and roughness of different CAD/CAM materials.

Sign Up to like & getrecommendations! Published in 2022 at "Clinical oral investigations"

DOI: 10.1007/s00784-022-04500-2

Abstract: OBJECTIVES This study evaluated the surface integrity of two types of diamond burs and their effect on the roughness of different CAD/CAM materials. MATERIALS AND METHODS CAD/CAM materials, Vita Mark II (VM), IPS e.max CAD… read more here.

Keywords: roughness; surface integrity; cad cam;

Experimental analysis of surface integrity of cemented carbides resulting from contemporary sinking EDM technology

Sign Up to like & getrecommendations! Published in 2019 at "Production Engineering"

DOI: 10.1007/s11740-019-00896-1

Abstract: The generator technology of electrical discharge machining (EDM) has evolved significantly over the last decades. This enabled EDM to become a crucial technology in die and mold manufacturing. Moreover, EDM became a more important technology… read more here.

Keywords: sinking edm; cemented carbides; edm technology; technology ... See more keywords

Flexible CNC polishing process and surface integrity of blades

Sign Up to like & getrecommendations! Published in 2018 at "Journal of Mechanical Science and Technology"

DOI: 10.1007/s12206-018-0530-0

Abstract: The surface integrity of aero-engine blades directly affects its mechanical behavior. To improve the surface integrity and address the problem, that is, the blade is mainly polished manually, a flexible polishing process was proposed and… read more here.

Keywords: polishing process; surface; surface integrity; flexible polishing ... See more keywords

Experimental Investigation of Surface Integrity and Multi-Objective Optimization of End Milling for Hybrid Al7075 Matrix Composites

Sign Up to like & getrecommendations! Published in 2020 at "Silicon"

DOI: 10.1007/s12633-020-00530-1

Abstract: Cost effective machining of hybrid metal matrix composites (HMMC’s) with required surface integrity and without surface flaws is a challenging task for modern industries. This research explores the effect of end milling factors (spindle speed,… read more here.

Keywords: hybrid al7075; surface; matrix composites; rate ... See more keywords

Surface Integrity Assessment Upon Electric Discharge Machining of Die Steel Using Non-Destructive Magnetic Barkhausen Noise Technique

Sign Up to like & getrecommendations! Published in 2020 at "Transactions of the Indian Institute of Metals"

DOI: 10.1007/s12666-020-01914-y

Abstract: Surface integrity characterization of manufactured component is very important as it significantly affects the in-service performance of the component. Till now, surface integrity was evaluated using conventional measurement technique like microhardness tester, X-ray diffraction, optical… read more here.

Keywords: technique; microscopy; surface; barkhausen noise ... See more keywords

Overall evaluation of the surface integrity in two-dimensional ultrasonic surface rolling 7050 Al alloy

Sign Up to like & getrecommendations! Published in 2020 at "Journal of the Brazilian Society of Mechanical Sciences and Engineering"

DOI: 10.1007/s40430-020-02423-1

Abstract: To improve the anti-fatigue performance and the service life of parts made of 7050 aluminium alloy, the surface integrity of the workpiece treated by two-dimensional ultrasonic surface rolling (TDUSR) was comprehensively evaluated, and the optimization… read more here.

Keywords: alloy; surface; two dimensional; evaluation ... See more keywords

Molecular dynamics study on the adsorption synergy of MWCNTs/MoS2 nanofluids and its influence of internal-cooling grinding surface integrity

Sign Up to like & getrecommendations! Published in 2021 at "Applied Surface Science"

DOI: 10.1016/j.apsusc.2021.150312

Abstract: Abstract The combination of nanofluids and internal-cooling grinding was applied in machining super-alloy to solve the problem of insufficient heat transfer and lubrication, thereby improving the surface integrity. In this paper, molecular dynamics method was… read more here.

Keywords: internal cooling; mwcnts mos2; surface; adsorption ... See more keywords

Improvement of surface integrity in the grinding of bioceramic partially stabilized zirconia using analytical, numerical, and experimental methods

Sign Up to like & getrecommendations! Published in 2020 at "Ceramics International"

DOI: 10.1016/j.ceramint.2020.02.168

Abstract: Abstract In the present paper, the impact of grinding on the surface integrity of the PSZ is investigated through analytical, numerical, and experimental studies. The analytical model of the single grit grinding of the PSZ… read more here.

Keywords: numerical experimental; improvement surface; surface; analytical numerical ... See more keywords

An investigation into the effect of surface integrity on the fatigue failure of AISI 4340 steel in different drilling strategies

Sign Up to like & getrecommendations! Published in 2019 at "Engineering Failure Analysis"

DOI: 10.1016/j.engfailanal.2018.08.022

Abstract: Abstract DTH bits often fail because of fatigue fracture at the machined holes location. In order to understand the failure mechanism and improve the fatigue life of drill bits, the effects of drilling parameters and… read more here.

Keywords: drilling; surface integrity; fatigue life; failure ... See more keywords

Risks related to the lack of lubrication on surface integrity in drilling

Sign Up to like & getrecommendations! Published in 2019 at "Heliyon"

DOI: 10.1016/j.heliyon.2019.e01138

Abstract: Drilling processes can significantly affect the surface integrity of metallic components. Thus, the control of the drilling process is of great interest for industry to ensure a satisfactory surface behavior. The understanding of such a… read more here.

Keywords: surface; lubrication surface; surface integrity; integrity drilling ... See more keywords

How does surface integrity of nanostructured surfaces induced by severe plastic deformation influence fatigue behaviors of Al alloys with enhanced precipitation?

Sign Up to like & getrecommendations! Published in 2020 at "International Journal of Fatigue"

DOI: 10.1016/j.ijfatigue.2020.105792

Abstract: Abstract Effects on fatigue behaviors and microstructures of Surface Mechanical Attrition Treatment (SMAT) before or after precipitation aging have been investigated on two hardenable Al alloys. The aluminum alloy with high notch sensitivity (7075) should… read more here.

Keywords: precipitation; fatigue; surface integrity; fatigue behaviors ... See more keywords