Fabrication of Titanium Aluminides via Powder cored wire‐arc additive manufacturing:Microstructural and Mechanical characterization

Sign Up to like & getrecommendations! Published in 2023 at "Advanced Engineering Materials"

DOI: 10.1002/adem.202201823

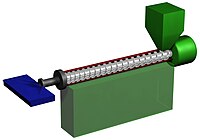

Abstract: Herein, an innovative powder‐cored wire arc additive manufacturing (PC‐WAAM) process is proposed to fabricate γ‐TiAl thin‐walled intermetallic alloy. The metallography, phase composition, and mechanical properties at different thin‐wall locations are characterized. The results show that… read more here.

Keywords: powder cored; wire arc; arc additive; manufacturing ... See more keywords

Influence of Feedstock Materials and Spray Parameters on Thermal Conductivity of Wire-Arc-Sprayed Coatings

Sign Up to like & getrecommendations! Published in 2017 at "Journal of Materials Engineering and Performance"

DOI: 10.1007/s11665-017-2567-0

Abstract: To manufacture a protective coating with high thermal conductivity on drying cylinders in paper production machines, a FeCrB-cored wire was developed, and the spraying parameters for wire-arc spraying were optimized in this study. The conventional… read more here.

Keywords: wire arc; influence feedstock; thermal conductivity; conductivity ... See more keywords

Numerical Investigation of the Effect of Rolling on the Localized Stress and Strain Induction for Wire + Arc Additive Manufactured Structures

Sign Up to like & getrecommendations! Published in 2019 at "Journal of Materials Engineering and Performance"

DOI: 10.1007/s11665-019-04249-y

Abstract: Cold rolling can be used in-process or post-process to improve microstructure, mechanical properties and residual stress in directed-energy-deposition techniques, such as the high deposition rate wire + arc additive manufacturing (WAAM) process. Finite element simulations of the… read more here.

Keywords: residual stresses; wire arc; effect rolling; stress ... See more keywords

Fabrication of Composite Heat Sinks Consisting of a Thin Metallic Skin and a Polymer Core Using Wire-Arc Spraying

Sign Up to like & getrecommendations! Published in 2019 at "Journal of Thermal Spray Technology"

DOI: 10.1007/s11666-019-00864-2

Abstract: Three composite heat sinks in the shape of a disk, a cylinder, and a cylinder with vertically projecting fins were made by applying a thin (0.4-0.7 mm) zinc layer onto ABS polymer cores using wire-arc spraying.… read more here.

Keywords: wire arc; using wire; heat sinks; polymer ... See more keywords

Microstructural Characteristics of Wire Arc Additive Manufacturing with Inconel 625 by Super-TIG Welding

Sign Up to like & getrecommendations! Published in 2020 at "Transactions of the Indian Institute of Metals"

DOI: 10.1007/s12666-020-01915-x

Abstract: Nowadays, the implementation of additive manufacturing (AM) is rapidly growing in various sectors. Many manufacturing industries are demanding an increase in the size of the AM parts. Wire arc additive manufacturing (WAAM) offers a high… read more here.

Keywords: wire arc; tig welding; super tig; tig ... See more keywords

A study on wire and arc additive manufacturing of low-carbon steel components: process stability, microstructural and mechanical properties

Sign Up to like & getrecommendations! Published in 2020 at "Journal of The Brazilian Society of Mechanical Sciences and Engineering"

DOI: 10.1007/s40430-020-02567-0

Abstract: Among metal-based additive manufacturing, wire and arc additive manufacturing is receiving increasing attention for the production of components with medium to large dimensions. In the current research, the production of low-carbon steel thin-walled components by… read more here.

Keywords: wire arc; low carbon; manufacturing; additive manufacturing ... See more keywords

A mechanical model in wire + Arc additive manufacturing process

Sign Up to like & getrecommendations! Published in 2020 at "Progress in Additive Manufacturing"

DOI: 10.1007/s40964-020-00112-y

Abstract: Material properties are dependent upon the microstructural characteristics of the part. Developing an accurate and sufficient representation of the microstructure obtained in metal additive manufacturing (AM) is critical to precisely estimate material properties. Since the… read more here.

Keywords: layer; wire arc; plastic strains; additive manufacturing ... See more keywords

Non-destructive testing for wire + arc additive manufacturing of aluminium parts

Sign Up to like & getrecommendations! Published in 2019 at "Additive Manufacturing"

DOI: 10.1016/j.addma.2019.100782

Abstract: Abstract Wire + Arc Additive Manufacturing (WAAM) has already proven to be successful for the production of large metal parts. However, there are still no specific standards available to label the quality requirements of the parts produced… read more here.

Keywords: wire arc; manufacturing; non destructive; arc additive ... See more keywords

Grain refinement in an unalloyed tantalum structure by combining Wire+Arc additive manufacturing and vertical cold rolling

Sign Up to like & getrecommendations! Published in 2020 at "Additive manufacturing"

DOI: 10.1016/j.addma.2019.101009

Abstract: Abstract Components manufactured via Wire + Arc Additive Manufacturing are usually characterised by large columnar grains. This can be mitigated by introducing in-process cold rolling; in fact, the associated local plastic deformation leads to a reduction of… read more here.

Keywords: wire arc; additive manufacturing; structure; grain ... See more keywords

Hot forging wire and arc additive manufacturing (HF-WAAM)

Sign Up to like & getrecommendations! Published in 2020 at "Additive manufacturing"

DOI: 10.1016/j.addma.2020.101193

Abstract: Abstract In this study, we propose a new variant of wire and arc additive manufacturing (WAAM) based on hot forging. During WAAM, the material is locally forged immediately after deposition, and in-situ viscoplastic deformation occurs… read more here.

Keywords: manufacturing waam; wire arc; additive manufacturing; arc additive ... See more keywords

A probabilistic approach for high cycle fatigue of Wire and Arc Additive Manufactured parts taking into account process-induced pores

Sign Up to like & getrecommendations! Published in 2021 at "Additive manufacturing"

DOI: 10.1016/j.addma.2021.101989

Abstract: Abstract Wire and Arc Additive Manufacturing (WAAM) is a direct-energy deposition technique (unlike SLM or EBM) that builds up a part in a layer-by-layer fashion, each layer being constituted of interlaced weld beads. It is… read more here.

Keywords: fatigue; cycle fatigue; wire arc; high cycle ... See more keywords