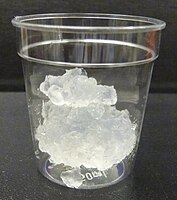

Photo from wikipedia

Abstract Membrane process is used to decontaminate dye wastewater. In the process of separation, the adsorbed and/or rejected dyes can greatly foul the membrane and negatively affect separation efficiency. Fenton… Click to show full abstract

Abstract Membrane process is used to decontaminate dye wastewater. In the process of separation, the adsorbed and/or rejected dyes can greatly foul the membrane and negatively affect separation efficiency. Fenton oxidation can non-selectively mineralize dyes to prevent fouling the membrane. Therefore, this work focused on synthesizing the membrane coupled with Fenton catalyst for dye wastewater treatment. Polyacrylonitrile (PAN)/poly (acrylic acid) (PAA) composite nanofiber membrane was first prepared by layer-by-layer sequential electrospinning and then served as the substrate to load iron ions by the coordination of carboxyl groups of PAA with iron ions, after which a catalytic membrane was successfully prepared. During the application process, water would inevitably elute some iron ions from the catalytic membrane. In order to minimize the loss of iron ions, another PAA/PAN composite nanofiber membrane with the function of rejecting iron ions was then designed and superimposed onto the catalytic membrane using the adhesiveness of upper PAA layer. In this sense, the obtained composite membrane can stably catalyze H2O2 to effectively oxidize methylene blue (MB) due to low leaching-out of iron ions. The results showed that the iron ion loading ratio of PAN/PAA composite nanofiber membrane was increased by 167% compared to that of PAN nanofiber membrane, and the total iron ion elution ratios of PAN nanofiber membrane and PAN/PAA composite nanofiber membrane were 27 times and 6 times higher than that of superimposed composite membrane, respectively. As a result of high loading and low elution of iron ions, the superimposed composite membrane exhibited considerably stable efficiency for MB removal within 30 operation cycles, which reached up to 97.0%. Additionally, the superimposed composite membrane presented better mechanical property and more adjustable permeation flux than the control membranes, so that it would show a great potential for the application in the field of dye wastewater treatment.

Journal Title: Journal of Membrane Science

Year Published: 2022

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!