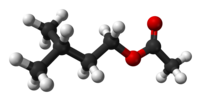

Photo from wikipedia

Nowadays, isoamyl acetate production is carried out by chemical synthesis with a recent interest in developing biological producing processes, mainly based on microorganisms in submerged fermentation. This work assayed producing… Click to show full abstract

Nowadays, isoamyl acetate production is carried out by chemical synthesis with a recent interest in developing biological producing processes, mainly based on microorganisms in submerged fermentation. This work assayed producing isoamyl acetate through solid-state fermentation (SSF), feeding the precursor in the gas phase. Polyurethane foam functioned as the inert support to contain 20 ml of a solution of molasses (10% w/v, pH 5.0). The yeast Pichia fermentans was inoculated at 3 × 107 cells per gram of initial dry weight. The airstream to supply oxygen also served to supply the precursor. Slow supply was obtained using an isoamyl alcohol solution of 5 g l-1 in the bubbling columns and an air stream of 50 ml min-1. For fast supply, fermentations were aerated using 10 g l-1 and 100 ml min-1 for isoamyl alcohol solution and air stream, respectively. It demonstrated the feasibility of isoamyl acetate production in SSF. Moreover, the slow supply of the precursor increased isoamyl acetate production up to 390 mg l-1, which is 12.5 times higher than that obtained without precursor (32 mg l-1). On the other hand, fast supply caused an evident inhibition of the growth and production capacity of the yeast.

Journal Title: Letters in applied microbiology

Year Published: 2023

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!